Do you have a keen interest in learning new programming languages? Are you detail-oriented, like the analytic, and enjoy industrial automation? If so, becoming a programmable logic controller (PLC) engineer could be the right job for you.

Programming, not to be confused with coding, is a paramount skill for PLC engineers. There are five languages you’ll need to learn before entering the field. We’ll explore that and more below to guide you on the path of becoming a successful PLC engineer.

What Is a Programmable Logic Controller or PLC?

A programmable logic controller is an industrial computer that controls other systems, acting as a central hub. They are quite different from your normal office computer and are designed to operate reliably in harsh environments. These machines can withstand things like frequent vibrations or extreme temperatures.

Five different programming languages are inputted via a central processing unit to operate this complex system. Out of the over 700 programming languages you can learn, very few are skilled in these five languages. With the right education, you’ll surely be in high demand.

These digital computers are used often in manufacturing and production lines. They are the “brains” of the system, monitoring inputs and outputs, and guiding machines and automated processes.

One example of a PLC is the Allen-Bradley PLC rack, which includes a central processing unit as well as a programming device to handle industrial automation.

What Is a PLC Used For?

Believe it or not, these computers have been around since the mid-60s. They have been a mainstay since then in manufacturing and operational industries. Below are five areas where you can find PLCs.

- Wind turbine operation. These controllers are used effectively in wind-turbine operations by providing accurate and up-to-date data as well as helping to monitor things like downtime.

- Cement manufacturing. This is another industry that commonly uses control systems. Within cement production, PLCs regulate the mixing of raw materials and analyze the final product for quality.

- The smart factory. Smart factory initiatives include intelligent automation, advanced robotics, and the use of the Internet of Things (IoT). Even with rapid technological change, PLCs continue to play an essential role as a central processor for real-time decisions in manufacturing.

These computers send a wide range of detailed data that can be integrated with cloud computing to help perform tasks like scheduling jobs, handling logistics, and communicating with suppliers.

- Glass production. This industry also makes use of PLCs. They are used in many tasks and workshop processes like controlling material ratios, processing flat glasses, and more.

- Virtual modeling. A virtual modeling system is helpful for a plant manager who needs to rearrange a production line. When 2D specifications aren’t enough, more complex modeling comes in handy. That’s where PLCs can help.

Five Types of PLC Programming Languages

If PLCs are a new concept for you, perhaps learning one or two of their more common programming languages is a good first step. Below are five of the most-used PLC programming languages.

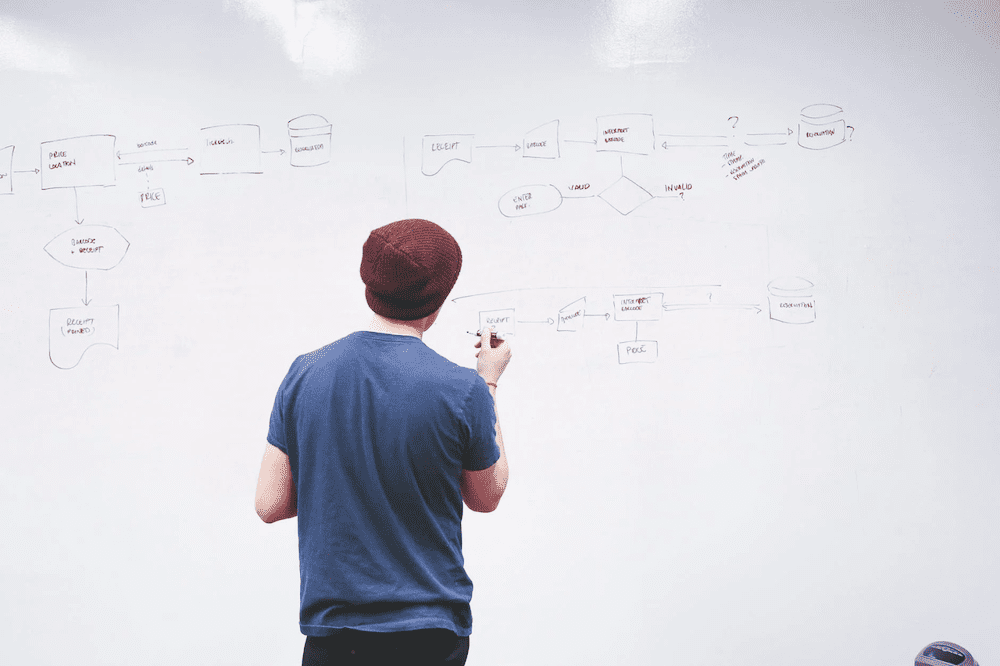

Sequential Function Charts (SFC)

Those who know flow charts can familiarize themselves with this programming language more readily. However, the SFCs might have more branches than you’re used to seeing. This language uses lots of steps and transitions to get the correct result.

Anyone learning to become a full-stack developer or programmer will already know this language. Or those who know flow charts can familiarize themselves with this programming language more readily. However, the SFCs might have more branches than you’re used to seeing.

This language uses lots of steps and transitions with binary conditions to get the correct outcome. Decisions in this language are based on timing, phases, and even the physical state of the equipment.

Ladder Diagram (LD)

This type of PLC programming language is unlike any coding you might learn for your computer. The language uses ladder diagrams to show logic relations. This relay-logic partially relies on components like physical-mechanical relays and switches. The novel method of ladder diagrams is used to run industrial automation applications.

Structured Text (ST)

The third language is called structured text. This high-level language resembles Pascal, “C,” and Visual Basic. It supports complex statements and nested instructions, which is especially useful in industry.

Function Block Diagram (FBD)

This PLC programming language leans towards the graphical. Its layout displays inputs and outputs in blocks attached by connection lines. The engineer will program function blocks for the PLC to run. This type of system is great for repetitive tasks like loops, timers, and counters.

Instruction List (IL)

The last PLC language is the instruction list. Similar to structured text, this assembly language is also based on text. It’s written using mnemonic codes like “or,” “and” and “load.” This is great for applications that are time-critical and compact.

Learning All About PLC Programming Languages

Once you have had your “Aha!” moment and decide this is the career path for you, assess your current skills to determine whether you need a basic refresher course in programming. Next, get started on learning the five languages described above. Don’t worry, some of the easiest programming languages to learn include those just mentioned.

How Long Does It Take to Learn PLC Languages?

Your background, level of experience with programming, and the application you are most comfortable with will determine the time it takes to learn a PLC language.

In an ideal world, you should learn all five programming languages. So pace yourself, study one at a time, and make full use of the resources we mention below.

How to Familiarize Yourself With PLC: Step-by-Step

Let’s say you are a newbie but the idea of learning a programming language for a PLC appeals to you. First, congratulations on choosing a path that will improve your technical skills and open numerous employment doors for you.

Next, below is a basic guide to get you on the right path. Before you know it, you’ll be a PLC expert.

- Start with a basic understanding. A typical shopper looking for a laptop online would first do some research on specifications, right? Similarly, you should do your research when learning about programming. For example, read up on what a programming language is and go from there.

- Dabble. How will you know if you like this field unless you try it out? Peruse various resources to find out what are the different types of languages. In the section above we mention how similar some of these languages can be. Why not dabble in Java for beginners to get an idea of how to structure code and instructions?

- The bigger picture. Don’t just stop at learning programming languages. Get a holistic idea of the job and skills needed by looking at some of the engineering pathways and jobs available. You could become both an engineer and a PLC programmer. Gain career leverage by doing extra work.

- Enroll in a course. Now you know what it takes to become a PLC programmer or engineer. The next step is to join a course online or in a classroom to learn how the experts do it. This can also help you apply some hands-on knowledge to your education.

- Get certified. Engineer and programmer jobs are in high demand. However, a certified professional has a better chance of landing their dream job.

The Best PLC Training Courses and Certifications

Many employers and organizations are on the lookout for those who know about PLCs and their various languages. Below are further resources, depending on your lifestyle and learning preferences, to help you achieve this goal.

Best In-Person PLC Classes

If you have the time, we highly recommend you learn by sitting in a classroom or taking up a virtual instructor-led class. Not only will you learn from some of the industry’s top experts, but you’ll also get to see and work on real-life controllers. This will help you with both theoretical and practical knowledge. A few such classes have been included below.

Programmable Logic Controllers – EAL Level 3 Qualification

- Instruction method: In-person, instructor-led

- Time: 10 Days

- Dates: Varies according to location. Nov. 23 – June 28

- Prerequisites: None

- Cost: $2,000 including VAT

This in-person, 10-day training course is accredited by City & Guilds. By the course’s end, you’ll have a Level 3 EAL award in PLCs as well as a City & Guilds certificate.

The extensive training includes instruction on operating some of the more than 20 PLC machines including those from Allen Bradley, Siemens, and Mitsubishi. The course is 90 percent practical and 10 percent theory. Notes and a USB with learning material are provided at the end of the course.

Best Online PLC Training and Certification Courses

The second option is to go for some of the best online courses available. With these, you’ll learn how to work on some of the most popular PLC systems.

Learn 5 PLCs in a Day – Allen Bradley, Siemens, Schneider, Omron & Delta

- Instruction method: Online downloadable resources, self-paced

- Provider: Udemy

- Time: 26 hours for 20 articles and 50 downloadable resources

- Dates: Full-time access

- Prerequisites: None

- Cost: Discounted fee at $12 (normal price $40) until the end of November 2020

This is a course built for programmers, engineers, and technicians. Besides knowing how to wire and connect PLCs, it is essential to learn how to program them. Learning it all will help you troubleshoot efficiently. This course video teaches you about circuit diagrams, programming a PLC for any project, industrial application, and home and factory automation systems.

"Career Karma entered my life when I needed it most and quickly helped me match with a bootcamp. Two months after graduating, I found my dream job that aligned with my values and goals in life!"

Venus, Software Engineer at Rockbot

These live-recorded sessions can be accessed at any time. But hurry and enroll for that discounted price.

Allen Bradley PLC Training – RSLogix 5000 Series

- Instruction method: Online downloadable resources, self-paced

- Provider: Udemy

- Time: 21.5 hours

- Dates: Lifetime access

- Prerequisites: None

- Cost: $30

Once you have completed this online course, you should be able to set up and program a Rockwell Automation in RSLogix 5000 and Studio 5000. This course is for those who are familiar with PLCs but want to learn about different systems

Best Free PLC Courses

Our next option for you is free courses, available from multiple providers. These range from the beginner to the intermediate level.

Free PLC Training: Learn PLC Programming Online

- Instruction method: Various online videos and articles

- Provider: PLC Academy

- Dates: N/A

- Prerequisites: None

- Cost: FREE

This site is dedicated to teaching all about PLC programming. They offer many free resources so take advantage.

PLC Technician Training

- Instruction method: Online videos

- Provider: George Brown College

- Dates: Varies

- Prerequisites: None

- Cost: Varies

This is another helpful resource provided by George Brown College and includes both free and paid courses. There are online videos you can access for free as well as certified registered training programs. Some courses apply the pay-as-you-learn model whereby you only pay for courses you take.

Best PLC Books

Books are everywhere on this topic. So invest in a text or two to take a break from your screen or partake in some bed-time reading. Check out a few options below.

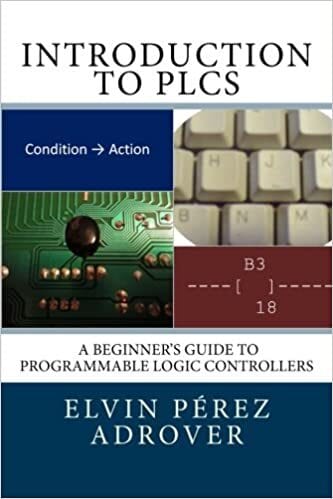

Introduction to PLCs: A Beginner’s Guide to Programmable Logic, Elvin Perez Adrover

It’s always advisable to start from the basics when learning a new subject. And this book will teach you just that. Read this to learn how PLCs play an essential part in industrial automation systems.

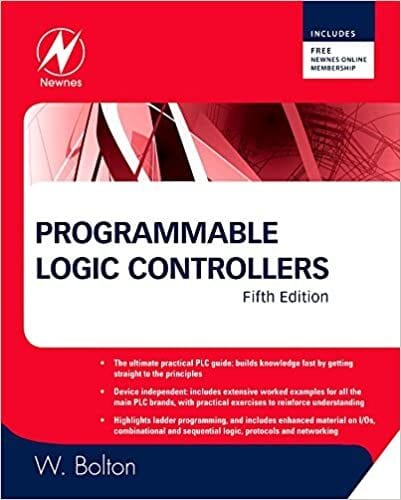

Programmable Logic Controllers, W. Bolton (2009)

This in-depth guide on PLCs includes lessons on electrics, controllers, and temperature gauges. What are actuators and sensors? Find out here. Extensive examples and practice problems are included to prepare you for the real-world.

Best Online PLC Resources

Once you have been through the introductions on this fascinating subject, head to any one of these online resources below for a deeper understanding. Stay connected to the PLC community via forums, free discussion groups, and company communities.

Quora.com

This popular free learning platform offers vital information and educational resources to learners and employees alike. Ask a question or go through a list of answers for various PLC topics. And discuss your queries with experts from all over the world.

ScienceDirect.com

ScienceDirect is a great resource where you can search PLC topics based on keywords, authors’ names, book titles, and volumes. Explore the information provided at your own pace. A good idea is to register so you can stay up to date on PLC news.

Should You Become a Programmable Logic Controller Programmer or Engineer?

This is a technical and hands-on career. If you’re interested in learning how to communicate with powerful machines using unique languages, then this could be the job for you. Consider taking a course or browsing the resources provided here.

About us: Career Karma is a platform designed to help job seekers find, research, and connect with job training programs to advance their careers. Learn about the CK publication.